Keep the bearing and its surrounding environment clean. Even if tiny dust invisible to the naked eye enters the bearing, it will increase the wear, vibration and noise of the bearing.

Care must be taken during use and installation. Strong stamping is not allowed, direct hitting of the bearing with a hammer is not allowed, and pressure is not allowed to be transmitted through rolling elements.

Use appropriate and accurate installation tools, try to use special tools, and try to avoid using things like cloth and short fibers.

To prevent bearing corrosion, when handling the bearing directly, wash off the sweat on your hands and apply high-quality mineral oil before operation. Pay special attention to rust prevention during the rainy season and summer.

Bearing installation method

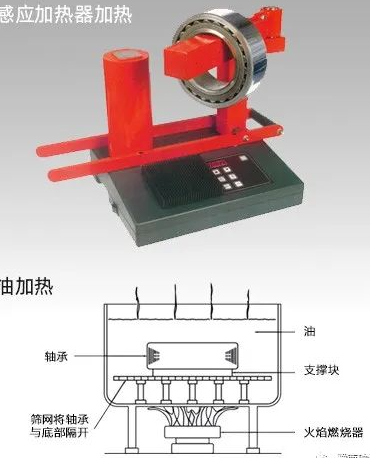

Heating method: It is recommended to use induction heater heating method, which is even, efficient and clean.

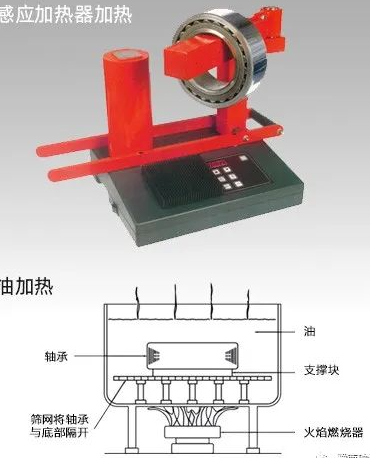

Oil heating method:

1. Do not heat the bearings above 120°C.

2. In order to avoid direct contact with the bottom of the oil tank, place the bearing on a metal mesh or hang it.

3. In order to avoid installation difficulties caused by cooling of the inner ring during operation, the bearing can be heated 20°C to 30°C higher than the required temperature.

4. After cooling down after installation, there will be axial shrinkage. In order to avoid a gap between the inner ring and the shaft shoulder, the nut on the shaft or other appropriate methods can be used to tighten it.

Frequently Asked Questions about the Installation and Use of Rolling Bearings

Q: Are there any requirements for the installation surface and installation location?

Answer: Yes. If there are iron filings, burrs, dust and other foreign matter entering the bearing, the bearing will produce noise and vibration during operation, and may even damage the raceways and rolling elements. Therefore, before installing the bearing, you must ensure that the mounting surface and installation environment are clean.

Q: Do bearings have to be cleaned before installation?

Answer: The bearing surface is coated with anti-rust oil. You must clean it carefully with clean gasoline or kerosene, and then apply clean, high-quality or high-speed and high-temperature lubricating grease before installation and use. Cleanliness has a great impact on bearing life and vibration and noise. But we would like to remind you that fully enclosed bearings do not need to be cleaned and refueled.

Q: How to choose grease?

Answer: Lubrication has an extremely important impact on the operation and life of bearings. Here you are briefly introduced to the general principles of grease selection. Grease is made of base oil, thickener and additives. The properties of different types of grease and different brands of the same type of grease vary greatly, and the allowable rotation limits are different. Be sure to pay attention when selecting. The main properties of grease

Determined by base oil. Generally, low-viscosity base oils are suitable for low temperatures and high speeds; high-viscosity base oils are suitable for high temperatures and high loads. The thickener is also related to the lubrication performance, and the water resistance of the thickener determines the water resistance of the grease. In principle, greases of different brands cannot be mixed, and even greases with the same thickener will have bad effects on each other due to different additives.

Question: When lubricating bearings, is the more grease the better?

Answer: When lubricating bearings, the more grease you apply, the better. This is a common misconception. Excess grease in bearings and bearing chambers will cause excessive mixing of the grease, resulting in extremely high temperatures.

Q: How to install and disassemble?

Answer: Do not directly hammer the end face and non-stressed surface of the bearing during installation. Press blocks, sleeves or other installation tools should be used to evenly stress the bearing. If the mounting surface is lubricated, the installation will go more smoothly. If the fit interference is large, the bearing should be placed in mineral oil and heated to 90~100℃ before installation immediately. When you encounter difficulties in disassembly, it is recommended that you use disassembly tools to

While pulling outward, carefully pour hot oil on the inner ring. The heat will cause the inner ring of the bearing to expand, making it easier to fall off.

Question: Is the smaller the radial clearance of the bearing, the better?

Answer: Not all bearings require minimum working clearance. You must choose the appropriate clearance according to the conditions. In the national standard 4604-93, the radial clearance of rolling bearings is divided into five groups - group 2, group 0, group 3, group 4, and group 5. The clearance values are in order from small to large, among which group 0 is the standard clearance. The basic radial clearance group is suitable for general operating conditions, normal temperatures and commonly used interference fits; bearings working under special conditions such as high temperature, high speed, low noise, and low friction should use large radial clearance; Bearings for precision spindles and machine tool spindles should use smaller radial clearances; roller bearings can maintain a small amount of working clearance. In addition, there is no clearance for separate bearings; finally, the working clearance of the bearing after installation is smaller than the original clearance before installation, because the bearing has to withstand a certain load rotation, and there are also friction caused by the bearing fit and load. The amount of elastic deformation.

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)